Did you know Houston professionals source over 50,000 custom door units annually for commercial projects? This staggering demand drives the need for suppliers who combine scale with craftsmanship. At our Hempstead Road facility, we deliver solutions that keep pace with the city’s booming construction sector.

We specialize in premium components crafted from Select American Hardwood or High Density Fiberboard. With 10 wood species and 32 finish options, our inventory supports everything from historic renovations to modern high-rises. Over 80% of repeat clients cite our hinge-boring precision and color-matching consistency as key reasons for partnership.

Our team serves contractors and designers across Harris County and beyond. Located at 12502 Hempstead Rd., we’re strategically positioned to meet tight deadlines without compromising quality. Custom sizing consultations and technical support ensure every order aligns with project blueprints.

Houston’s unique climate demands materials that withstand humidity fluctuations. We address this through moisture-resistant HDF options and climate-tested hardwood selections. This localized approach has made us the first call for professionals tackling projects from Downtown high-rises to Energy Corridor offices.

Key Takeaways

- Local expertise spanning Houston’s architectural and environmental needs

- 32 finish options across 10 wood species for precise project matching

- Central location at 12502 Hempstead Rd. for fast metro-area access

- Dedicated support including custom sizing and technical guidance

- Commercial-grade materials tested for Gulf Coast conditions

Introduction to Wholesale Cabinet Doors in Houston, TX

The heart of Texas homes lies in their design, starting with essential components that balance form and function. We’ve built our wholesale services around Houston’s need for precision-crafted elements that withstand daily use while elevating spaces. Over 300 local contractors trust our solutions for projects ranging from luxury high-rises to heritage home restorations.

| Style | Best For | Material Options |

|---|---|---|

| Flat Panel | Modern kitchens | HDF, Maple |

| Raised Panel | Traditional spaces | Oak, Cherry |

| Shaker | Transitional designs | Birch, Paint-grade HDF |

“The right finish transforms ordinary storage into design statements,” notes a Heights-based renovation specialist we’ve collaborated with since 2018. This philosophy drives our 32 finish options, including heat-resistant coatings for outdoor kitchens and stain-guard treatments for busy households.

Houston’s architectural diversity demands adaptable solutions. Our team analyzes project blueprints to recommend components that align with specific structural requirements. Whether matching historic Heights bungalow moldings or creating sleek lines for Memorial high-rises, we maintain 15,000+ units in ready-to-ship inventory.

Commercial partners benefit from our climate-conscious approach. High-density fiberboard options resist warping in Gulf Coast humidity, while hardwoods undergo moisture testing before delivery. This localized quality control ensures every piece performs as beautifully as it looks.

Our Office Location and Contact Information

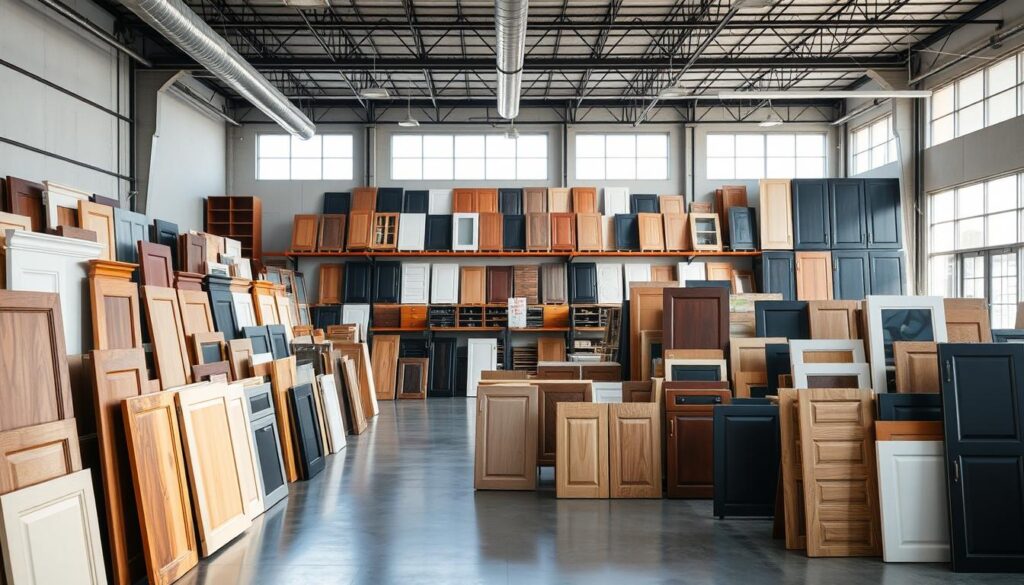

Houston professionals value face-to-face collaboration when selecting architectural components. Our 4,200 sq ft facility combines operational efficiency with hands-on design support, creating a hub for project planning excellence.

Visit Our Office

Find us at 12502 Hempstead Rd., where our showroom displays 150+ physical samples. Contractors compare wood grains, finish textures, and hardware compatibility under true-color lighting. Same-day pickup available for standard inventory items.

| Access Route | Travel Time | Landmarks |

|---|---|---|

| Via I-610 N | 12 minutes | Near Northwest Mall |

| From Highway 290 | 8 minutes | Next to Hardy Yards |

| Sam Houston Tollway | 15 minutes | South of Heights |

Working Hours & Contact Details

We align our schedule with construction industry needs:

| Day | Hours | Best For |

|---|---|---|

| Weekdays | 9 AM – 6 PM | Project consultations |

| Saturdays | 10 AM – 2 PM | Quick orders |

| Emergencies | Text +1 (713) 357-6373 | |

“Their team once stayed late to match a historic home’s original moldings,” shares a Memorial-area contractor. This commitment drives our flexible approach to urgent requests.

Reach our specialists through:

- Phone: +1 (713) 357-6373 (direct project line)

- Email: info@rtgcabinets.com (response within 2 hrs)

Book appointments online for complex projects requiring CAD reviews or custom finish testing. We reserve dedicated workstations for client collaborations every Thursday and Friday morning.

The Art of Crafting Premium Cabinet Doors

Creating durable, beautiful components requires both art and science. We blend hand-tool expertise with CNC precision to shape materials that withstand Houston’s humidity while maintaining visual appeal. Every piece starts with Select American Hardwood or High Density Fiberboard – materials chosen for their structural reliability and finish-ready surfaces.

Our craftsmen employ mortise-and-tenon joints alongside mitered edges, ensuring seamless alignment across all styles. Three-stage quality inspections verify grain consistency, hinge bore accuracy, and finish durability before any component leaves our workshop. This dual approach preserves traditional integrity while meeting modern performance demands.

“True artistry lies in making functional elements feel intentional,” observes a lead technician with 18 years’ experience. This philosophy guides our finishing processes, where layered stains and protective coatings enhance natural wood textures. We offer 32 finish options engineered to resist fading, scratches, and moisture penetration.

Consistency drives our production workflow. Grain-matching algorithms and batch-controlled staining ensure uniformity across large orders. Whether crafting 50 units or 500, we maintain dimensional tolerances within 1/32″ – a standard surpassing industry norms.

This meticulous approach transforms raw materials into architectural elements that perform as flawlessly as they look. Our craftsmen don’t just build doors; they create enduring design statements through calculated precision and material mastery.

cabinet doors : Quality and Design Diversity

Houston’s design landscape thrives on components that marry durability with visual impact. Our portfolio delivers this balance through 10 wood species, 23 paint colors, and 9 RTF finishes. This range empowers professionals to match projects ranging from Mid-Century Modern revivals to industrial-chic office spaces.

| Category | Options | Best For |

|---|---|---|

| Wood Species | 10 (White Oak to Walnut) | Natural texture enthusiasts |

| Paint Finishes | 23 curated hues | Trend-forward spaces |

| RTF Colors | 9 moisture-resistant | High-humidity zones |

White Oak and Cherry remain top choices for luxury residences, while Red Oak dominates commercial retrofits. “Our Memorial kitchen project required exact stain matching across 42 units – they delivered flawlessly,” notes a local designer. Such precision stems from batch-controlled production methods.

We extend customization beyond surfaces. Edge profiles and panel configurations adapt to structural demands. Transitional spaces benefit from Shaker-inspired lines, while Flat Panel styles anchor contemporary environments.

New thermofoil technologies address Houston’s climate challenges without sacrificing style. These innovations let designers specify bold colors for outdoor kitchens or medical facilities needing wipe-clean surfaces. Every option undergoes warping resistance tests before joining our catalog.

Materials and Manufacturing Techniques

In Houston’s humid environment, the right materials make the difference between fleeting trends and lasting beauty. Our production process combines scientific material selection with precision engineering to meet Gulf Coast demands.

Select American Hardwood vs. High-Density Fiberboard Options

We offer two foundational choices for professionals:

| Material | Benefits | Best Applications |

|---|---|---|

| Select Hardwood | Natural grain patterns Organic texture variation |

Historic renovations Luxury residences |

| HDF | Moisture resistance Consistent density |

Commercial kitchens Outdoor installations |

White Oak and Maple remain popular for traditional projects, while HDF excels in high-traffic areas. A Third Ward contractor recently noted: “Their HDF units outperformed solid wood in our medical facility retrofit.”

RTF and HDF Finishing Methods

Our thermofoil application process uses industrial-grade presses to bond finishes at 320°F. This creates seamless surfaces that:

- Resist peeling in 95% humidity

- Maintain color consistency for 10+ years

- Withstand chemical cleaners

CNC routers cut both materials with 0.02″ precision, ensuring perfect alignment. Separate production lines preserve material integrity – hardwoods get hand-sanded edges, while HDF undergoes robotic sealing.

Quality checks include moisture meters and adhesion tests. We verify every component meets Houston’s unique climate challenges before shipping. This dual focus on craftsmanship and science delivers components that age gracefully under pressure.

Exploring Flat Panel and Raised Panel Cabinet Doors

Houston’s architectural diversity demands components that balance aesthetic intent with functional precision. We guide professionals through panel selection processes that define spatial character while meeting practical demands.

Flat Panel Style Characteristics

Clean lines dominate our flat panel designs, featuring 1/4″ center panels framed with precision joinery. Mortise-and-tenon construction ensures lasting stability for high-traffic environments. These units excel in modern kitchens and office spaces requiring minimalist appeal.

Raised Panel Design Advantages

Solid wood center panels create dimensional depth that enhances traditional spaces. A Heights-based designer notes: “Raised profiles add heritage charm to transitional remodels.” We craft these units with moisture-resistant hardwoods ideal for Houston’s humidity.

Key differences drive specification decisions:

- Flat panels use HDF or maple for contemporary projects

- Raised designs employ oak or cherry for classic aesthetics

- Both styles offer mitered or mortise joinery options

Our team helps match panel types to structural requirements and design visions. Whether restoring Montrose bungalows or outfitting Midtown condos, we maintain 3,000+ flat and raised panel units in ready-to-ship inventory.

Trendy Shaker Cabinet Door Designs

Enduring design meets modern precision in our Shaker cabinet solutions. We’ve refined this American classic to meet Houston’s demand for versatile components that bridge eras and styles. Starting at $37.33 per unit, our best-selling design boasts a 4.94/5 satisfaction rating from local professionals.

True Shaker integrity begins with five-piece construction. Mortise-and-tenon joints create lasting stability, while recessed panels maintain clean proportions. Our craftsmen use Select Hardwood or moisture-resistant HDF, ensuring these units withstand Houston’s climate challenges.

“The subtle detailing works equally well in Rice Village condos and Katy farmhouses,” notes a designer who’s ordered 1,200+ units. We offer three profile depths and 14 finish options to match regional architectural diversity. Custom width adjustments maintain the style’s signature 1-3/8″ rail proportions.

Commercial partners appreciate our batch-matching precision across large orders. Grain alignment stays consistent within 1/32″, whether producing 50 or 500 units. This technical mastery preserves Shaker simplicity while delivering modern performance standards.

FAQ

Can I request custom sizes or finishes for drawer fronts?

Yes. We offer tailored dimensions, RTF (rigid thermofoil) coatings, and custom paint colors to match project requirements. Our team ensures precise alignment with your design specs, whether modern flat-panel or traditional raised-panel styles.

How long do orders typically take to fulfill in Houston?

Most orders ship within 5–7 business days. Lead times vary slightly for non-stock finishes or specialty styles like Shaker cabinet doors, but we prioritize local partners to minimize delays.

What makes raised panel designs ideal for commercial projects?

Raised panels add depth and durability, ideal for high-traffic kitchens. Their layered construction resists warping, and the classic profile pairs well with transitional or rustic aesthetics common in Texas homes.

Are your HDF options suitable for humid climates?

Absolutely. Our high-density fiberboard undergoes moisture-resistant treatment, making it a reliable choice for Houston’s subtropical environment. Combined with professional installation, it maintains structural integrity for years.

Do you provide matching drawer boxes with cabinet door orders?

Yes. We offer dovetailed drawer boxes in complementary finishes, ensuring cohesive aesthetics. Options include soft-close glides and full-extension hardware for seamless integration with your cabinetry.

How do flat-panel styles differ from Shaker designs?

Flat-panel doors feature a minimalist, smooth surface, while Shaker cabinet doors have a recessed center panel with clean, squared edges. Both work well in contemporary spaces, but Shaker designs offer more visual texture.

What sustainable practices do you follow in manufacturing?

We source FSC-certified hardwood and use low-VOC finishes. Our Houston facility recycles 95% of production waste, aligning with Texas’ growing demand for eco-conscious building materials.